DOCK APPROACH

An ideal design is a slightly inclined approach that does not inhibit the positioning of trailers, but allows water runoff away from the building. This also helps prevent the potential of damage to the building from trailers that are severely angled when positioned by jockey trucks.

Declined Approach

Declined approach areas are constructed when the floor of the building is even with the exterior grade level. To achieve a proper dock height for truck loading/unloading operations, the approach to the dock needs to be built incorporating a decline to the building.

There are some issues of concern with a declined approach to the dock. These include: difficult snow removal, water drainage, buildup of debris, and high impact forces to the dock. There is also the potential for serious damage to the building wall from impact by the top of the trailer. Approaching trucks can generate severe impact forces from only a short distance. Increased bumper projection or a projected dock must be provided to avoid building damage.

Special considerations must be made when incorporating other loading dock equipment with a declined dock approach. Dock seals need to be tapered to match the angle of the trailer. If the seals are not tapered, effective sealing will not be accomplished and dock seal damage is likely. Vehicle restraints must also be projected sufficiently to ensure proper operation and safety.

Overcoming impact to the building wall is easily accomplished. For new construction projects, the dock can be projected sufficiently to prevent the top of the trailer from impacting the building wall.

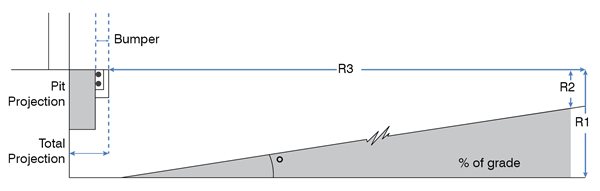

Required projection is determined based on the percentage of grade. To calculate the grade, measure the difference in height from the dock to a fixed point approximately 50' directly out from the dock. Divide the height difference by the length measured, using inches (eg. 18" difference over 600" distance. 18/600 = .03 x 100 = 3% grade) Declined approaches should not exceed a 10% grade for proper and efficient dock operations.

% of grade: (R1-R2) ÷ Run (R3)

Cantilevered Docks and Pit Projections

This configuration protects the building from trucks backing in.

Projection length increases proportionately to amount of decline or incline. If installing restraints, extensions plates must be ordered with the same projection.

Dock lip penetration (purchase) must be considered with projections and bumper sizes. A minimum of 4-6" lip penetration is required for safe dock operations